Powertrain Systems Solutions

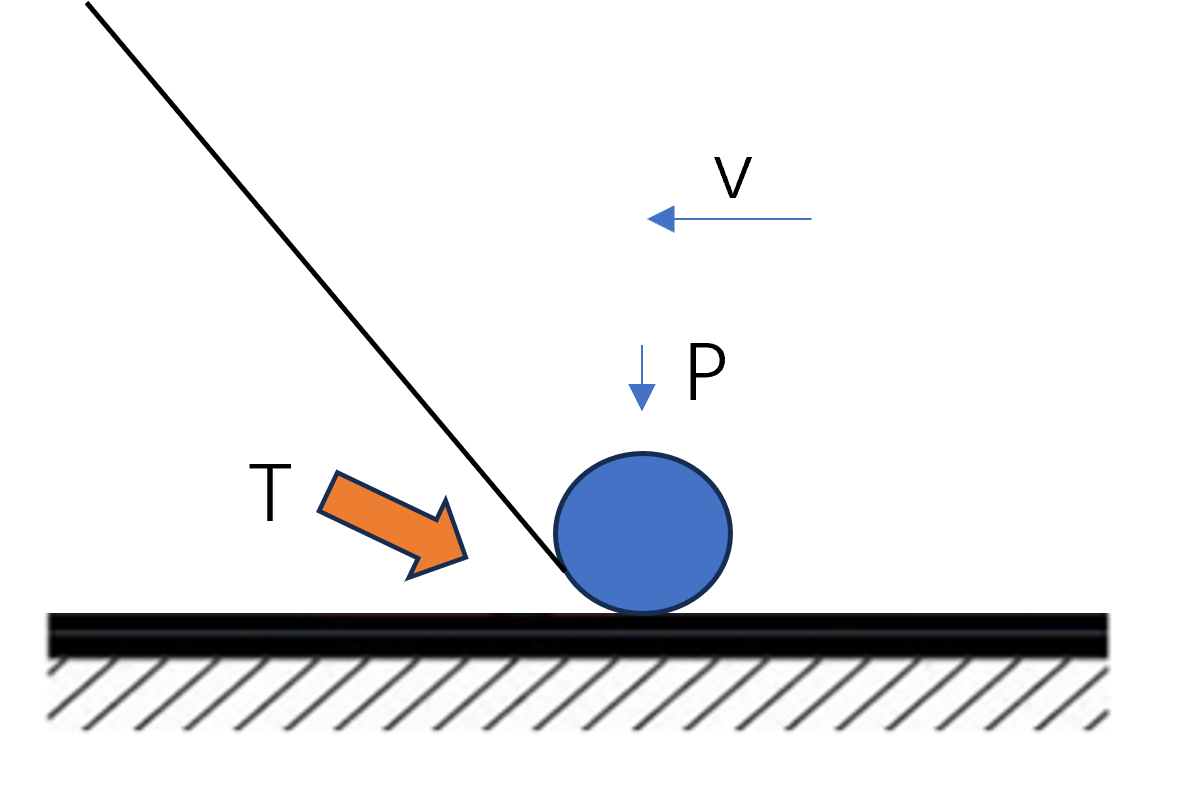

Wet winding: Porosity >1.5%, causing delamination at high RPM.

Epoxy curing: 2-3 hours, bottlenecking production.

oTKS LAB-L Laser-Assisted Dry Winding;

Real-time fiber tension monitoring (±1.5N accuracy);

Winding angle error <0.5°.

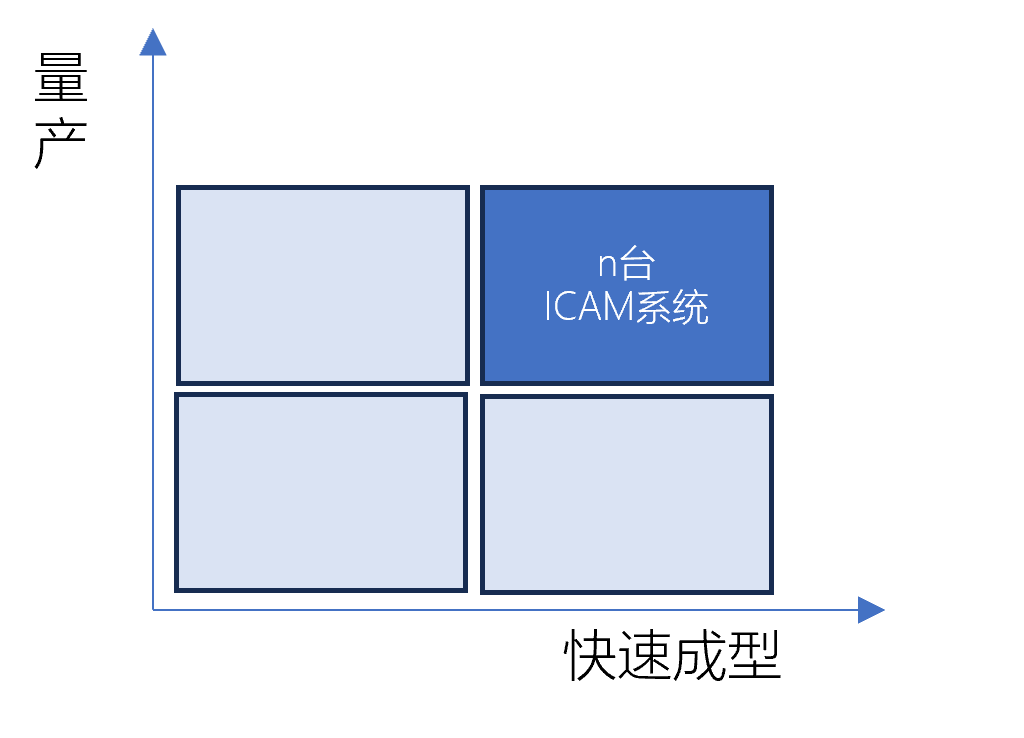

One-step rotor sleeve winding, 20% higher dynamic balance yield (CPK >1.5);

Thinner sleeves increase power density;

Higher radial pressure ensures sleeve integrity.